How to choose a suitable counting machine

2022-08-24 17:19:23

With

the expansion of production capacity,the packaging has become more

refined.There are more and more products packaged by number,and the

demand for counting is also increasing.There are many kinds of intelligent counting packaging equipment on the market. How to choose the counting equipment suitable for your production line?

According

to the counting principle,it is divided into three types of counting

equipment,weight counting, photoelectric counting and vision counting

-

Weight

counting,according to the weight of a single object and the total

weight,change into a number.The price is very cheap,but due to the

difference in the weight of a single object and the sensitivity of the

scale,there is an error in the number.

-

Photoelectric

counting,the material passes through the sensing area of the

photoelectric sensor,and the quantity is calculated because the light

path is blocked. If the materials overlap or fall seamlessly and

continuously,it can only be calculated once,causing errors.Therefore,the

photoelectric counting equipment needs to be equipped with a vibrating

plate to allow the materials to fall one by one in an orderly manner.

The speed is slow,and the compatibility of the vibrating plate is

low,but the price is cheap.

-

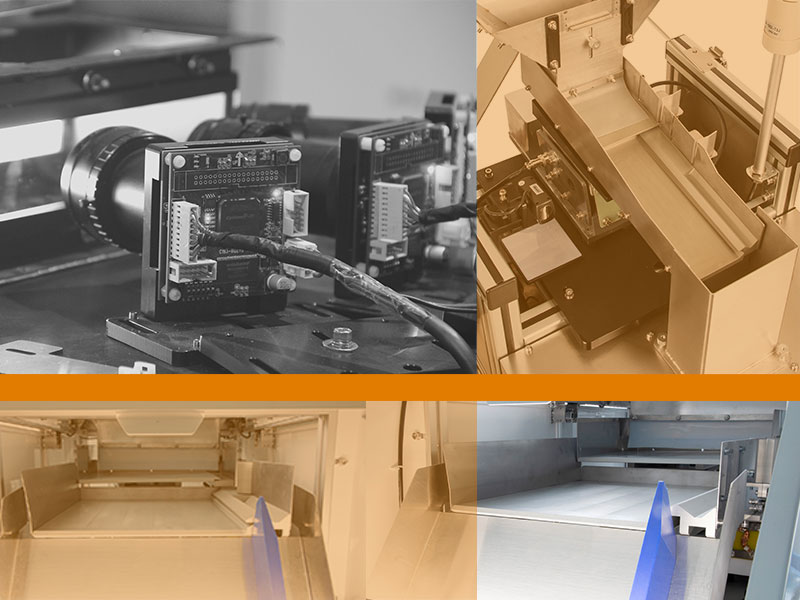

Vision counting,through

high-speed line array camera with algorithm, intelligent

identification.The feeding mechanism adopts the mode of coarse feeding +

fine compensation,with high precision and fast speed.Moreover, the

compatibility of the machine is good,and one piece of equipment can

count many kinds of materials.The overlap can also be counted

accurately,but the price is high.

The company can choose according to different product characteristics,packaging requirements,packaging speed and budget.

-

The individual weight difference of the product is very small,and the weight of the product is suitable for weight counting.

-

The

individual product weight varies greatly,and the weight of the product

is small,suitable for choosing vision counting or photoelectric

counting.

-

If the speed

requirement is low,the unit price of each product is low,and it can be

used for photoelectric counting.For example,the material diameter is

3mm, and it can count 2000-3000pcs per minute.

-

If

the unit price of the product is high,the customer requires the

quantity of each package to be precise,the speed requirement is high and

the material variety is large,then the vision counting machine is the

first choice.For the high speed vision counting machine,the

material with a diameter of 3mm can count 12000 pcs per minute.Because

the sorting accuracy is high,material waste is reduced, and customer

complaints are avoided.Although the price is higher than that of weight

and photoelectric counting equipment,but one equipment can count

multiple materials,which is more applicable and cost-effective.

Video